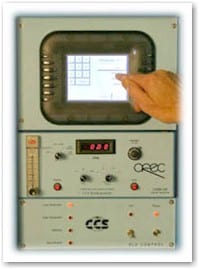

A factory upgrade for your existing OREC 0500 and 0900 Series Ozone Test Chamber is now available! The upgrade provides an opportunity to upgrade your existing OREC ozone chamber to all digital PLC controls with touchscreen interface, and improve the overall performance and reliability of your equipment.

The upgrade process involves removal of all existing control equipment including:

- Chart recorders

- Temperature controls

- Heater and UV lamp power controls

- Power supply

- Associated control wiring

- Switches and other user interface controls

- Temperature probe

The new control system includes:

- PLC

- Touchscreen interface

- Solid state, digital power controllers

- Relays

- Temperature probe

- DC Power supply

- Signal conditioning

Items retained:

- Ozone generating equipment

- Power wiring, fuses, breakers, etc.

- Dynastretch components

- Circulation and inlet blowers

- Heater

- Ozone Monitor

- All cabinet hardware and sheetmetal

After the installation of the new controls the equipment is thoroughly commissioned, calibrated, and certified to ISO-17025 standards.

Any equipment that is not included in the controls upgrade that is found to be non-functional or non-serviceable can be replaced at the time of upgrade under a separate contract. Other upgrades to give additional capabilities can also be performed at this time.

Ask for Price

The temperature and ozone settings are entered via the newly developed touch—screen. This digital display is an intuitive, easy—to—use interface which integrates alpha—numeric and graphical representations into a complete “control system”.

The PLC (programmable logic controller) system automatically compensates, in a rapid and accurate fashion, for external factors such as temperature and humidity, employing solid state digital electronics. This is a vast improvement in reliability, repeatability, and reproducibility in comparison with older analog or mechanized controls.

Additionally, the PLC improves:

- technician training requirements;

- time needed for observation during “unattended” operations,

- response to set point changes,

- resumption of O3 levels between test cycles.

The user defined test parameters are also entered using the PLC touch—screen system, which is designed to avoid inadvertent input. A newly developed electromagnetic door interlock system prevents accidental interruption of the test cycle which improves integrity and enhances overall safety.

This ultraviolet measurement and control system has many advantages over manual or chemical systems. The most significant of which are the elimination of:

- manual analytical titrations;

- air or solution flow adjustments;

- storing, measuring and mixing of chemicals;

- solution replenishment;

- time consuming efforts of skilled laboratory technicians.

The OREC™ ultraviolet automatic measurement and control system also has advantages which include:

- PLC ozone concentration control and digital touch—screen interface;

- Samples can be withdrawn from the chamber with rapid resumption of test concentrations;

- Change from one concentration level to another can be accomplished within a few minutes;

- Ozone tests can proceed unattended with complete automatic control and recording of ozone chamber concentrations over time.

Ozone is formed when oxygen molecules are split as they pass through a gap formed by a high voltage electrode. High voltage, at high frequency, is applied to the electrodes and the plasma formed in the gap is known as a silent arc discharge, and it is here that some of the oxygen molecules split and recombine to form ozone.

OREC™ Corona Discharge The silent arc discharge is also known as “corona discharge”. As the oxygen molecules pass through the electrode gap, the plasma is attended by a bluish halo or “corona”.

The corona discharge is the most practical, reliable, precise and cost effective alternative upon which to base the design of higher concentration ozone generators, while ultraviolet ozone generators are practical for lower generation requirements.

The OREC™ corona discharge system is an integral, totally self-contained, ozone generator manufactured from the highest quality materials and state-of-the-art technology.

It includes variable ozone control, flow control, reactor pressure and ozone output. Each corona discharge ozone generator receives a factory calibration certificate indicating the ozone output and conditions during testing under standard laboratory conditions.

- Custom designed chambers for special applications;

- Model W test chamber stand;

- DynaStretch™ dynamic stretching apparatus (ASTM D3395 Method A);

- Static stretching apparatus (ASTM D3395 Methods A, B, and C);

- Fixture and cutter for D1149;

- Triangular mold (ASTM D1171);

- Refrigeration for sub—normal temperature testing;

- DAQ—Zone, data acquisition & analysis software package;

- Second UV lamp.

Additional information on the OREC™ optional features is available, please visit the OREC™ Accessories pages.

OREC, Ozone Research Equipment Company, 0500, 0900, ozone test chambers, ozone, ozone destruction, ozone generation, ozonator, ozone generator, ozone test chamber, ozone monitor, Osmonics, ASTM D518, ASTM D1149, ASTM D1171, ASTM D3395, ASTM D4575, ASTM D470, ISO 1431, ozone research, rubber cracking, ozone resistance, rubber, crack growth, weathering, rubber deterioration, surface cracking, ozone cracking, ozone measurement, rubber test, ultraviolet, UV, 0550, 0950.