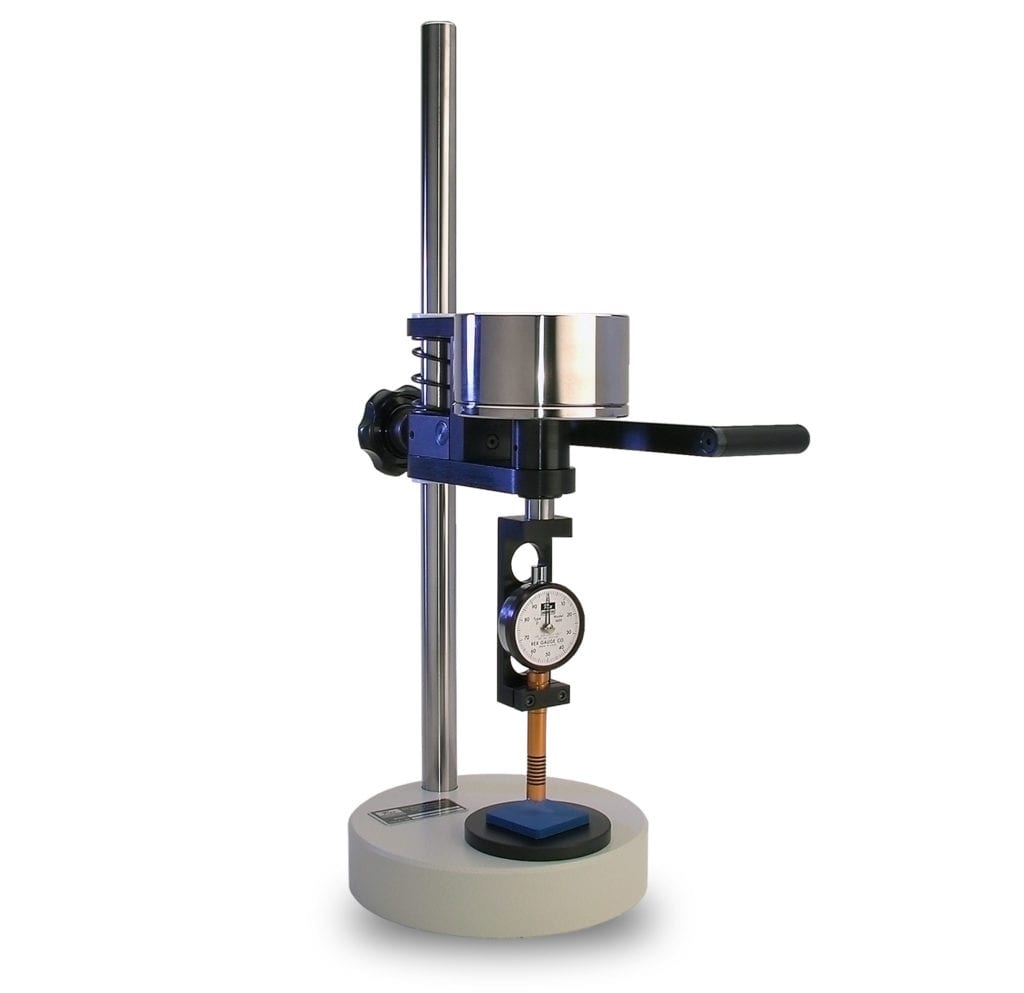

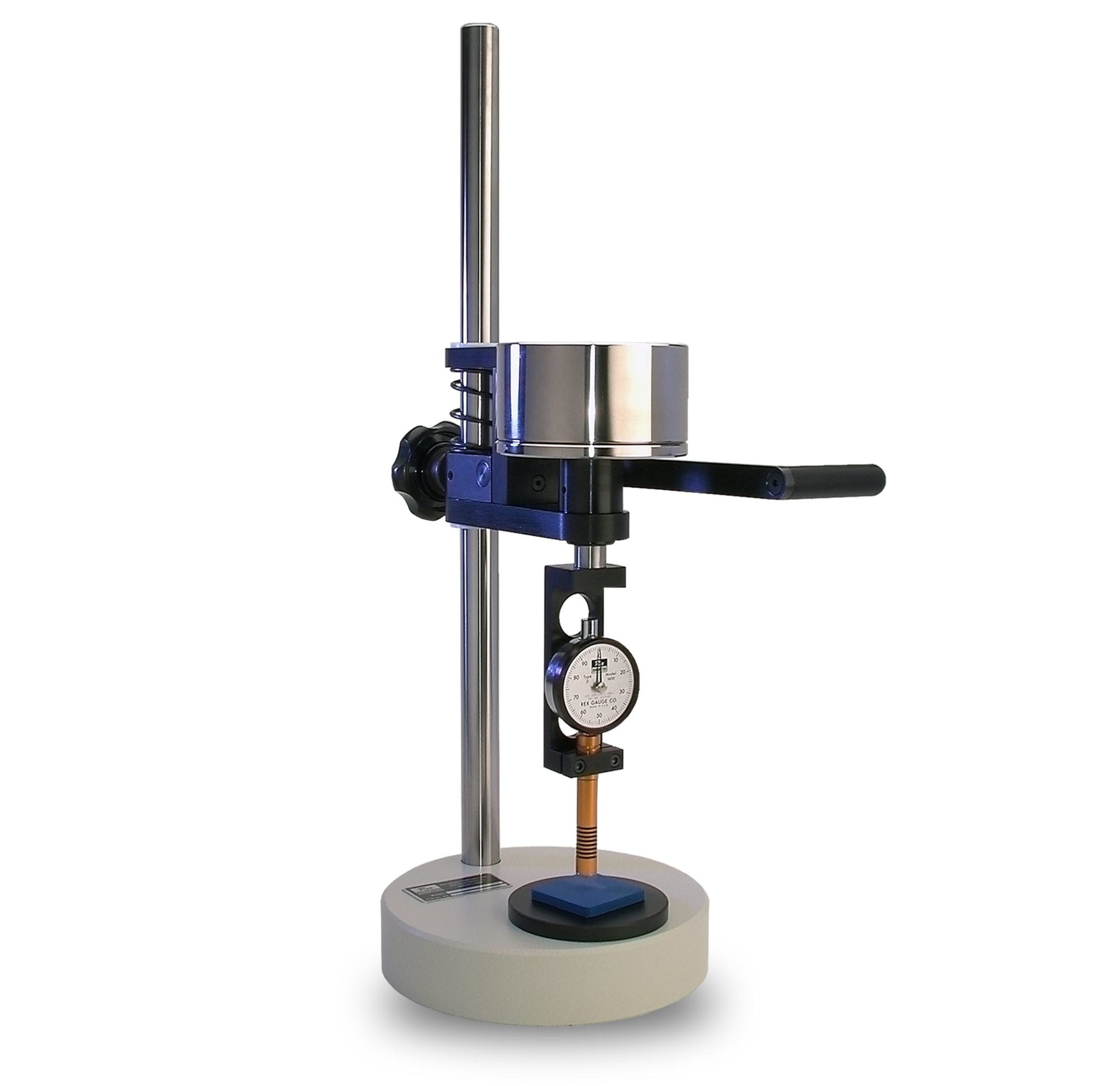

Rex Durometer Operating Stand: Models OS—1

The operating stand’s primary function is to increase the accuracy, precision, repeatability and reproducibility of the hardness determinations made with Rex durometers.

Rex operating stands are designed to assure that the durometer presser foot is parallel to the specimen table, hence a perpendicular application of the indentor to the test specimen.

The employment of an operating stand also allows for precise positioning of the specimen, assuring proper distance intervals between multiple determinations.

The Rex OS-1 Operating Stand is the ideal tool for repetitive or lab-type testing for users who must test either very large specimens, or test in a number of different durometer scales. The Rex OS-1 Operating Stand, used in conjunction with a Rex durometer eliminates the operator error sometimes associated with shop floor durometer testing. The stand features a floating pin and includes the proper load weights required for testing in durometer scales (A, B, C, D, DO, O, OO, OOO, OOO-S, and E), as noted in ASTM D2240. The OS-1 can accommodate specimens varying in size from a ¼: to 10 inches thick. (custom stands for testing larger specimens available).

Features:

- Eliminates operator error in ALL durometer scales (except M)

- Stainless steel and anodized aluminum construction

- Large size: 23″ high x 8″ wide

- Made in the USA

For models 1600, 2000, 3000, 4000, 5000, DD-4, and DD-5; Types A, B, C, D, DO, O, OO, OOO, OOO-S, and E

$1,495.00

| Model | OS-1 |

| Durometer Scale: | A, B, C, D, DO, O, OO, OOO, OOO-S, and E |

| Durometer Compatibility | 1600, 2000, 3000, 4000, 5000, DD-4, and DD-5 |

| Dimensions | 23" x 18" |

Index Terms: Rex Durometer, Rex Durometers, Shore hardness, pocket durometer, Shore scale, automatic operating stands, durometer operating stand, durometer stand, operating stand, hardness, rubber hardness, plastic, plastic hardness, indentation hardness, ebonite, ebonite hardness, rubber hardness testing, rubber testing, hardness testing, durometer hardness, testing, ASTM D2240, D2240, ASTM D1957, ISO 868, ISO 7619, JIS K6253, JIS K6251, JIS K6252, JIS K 6253, JIS K6254, JIS K6255, JIS K6256, JIS K6257, JIS K6258, JIS K6259, JIS K6260, DIN 53505, DIN 53 505, CNS, K6898, BS 903, BS 2782, BS ISO 21509, BS EN ISO 868, GB/T 10807, Asker, Asker C, SRIS0101, MIL-STD-45622A, MIL-I-45208A, MIL-STD-120, 83.060, 83.080.01, hysteresis, creep, Young’s Modulus.