The instrument is also designed the for the determination of the lowest temperature at which rubber vulcanizates and rubber coated fabrics will not exhibit fractures or coating cracks when subjected to specified impact conditions, as described in ASTM D2137 “Standard Test Methods for Rubber Property-Brittleness Point of Flexible Polymers and Coated Fabrics.” 2

The Temperature Retraction (TR) and Brittleness Point Tester is also employed for the determination of the temperature at which plastics and elastomers demonstrate failure (by impact) when brittle, as described in ASTM D746 “Standard Test Method for Brittleness Temperature of Plastics and Elastomers by Impact.”

CCSi manufactures the test specimen cutting dies for ASTM D746 Types I, II, and III, D1329 (25, 38, and 51 mm) , and D2137 Types A and B.

1 Related Methods, Temperature Retraction (TR) Test:

- ISO 2921

- BS 903-A29 (UK)

- NF T4NF T46-032 (France)

2 Related Methods, Brittleness Point Test:

- ISO 812

- DIN ISO 812 (Germany)

- BS 903-A25 (UK)

The structure of the Low Temperature Check has been designed to permit the installation of apparatus for TR and Brittleness point tests.

The structure includes all common parts required for low temperature testing:

• 5 litres thermal insulated stainless steel bath for cooling liquid.

• Heat exchangers for bath cooling & thermal resistance for bath heating

• Temperature controller with 0.1°C resolution

• Stirrer for bath homogenization

• Electronic card for the complete control fitted with USB port for connection to PC.

• Safety devices: independent bath overheating controller, thermal switch, pneumatic lock for sample holders.

The most important features are:

• Automatic temperature adjustment based on the selected test procedure

• Possibility to configure the instrument for the execution of TEMPERATURE RETRACTION (TR) and / or BRITTLENESS POINT tests

• Automatic execution of the entire test cycle in compliance with international standards

• Automatic recording of retraction curves

• Saving of curves and numerical results in the standard Gibitre SQL database

• Possibility of configuring the instrument for cooling via liquid nitrogen tank and refrigeration unit

• Nitrogen tank

• Refrigeration unit.

Ask for Price

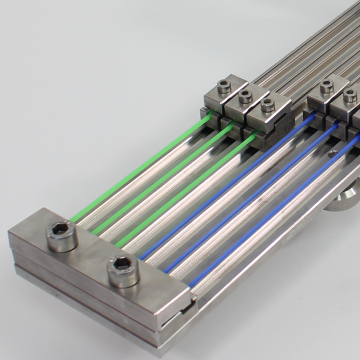

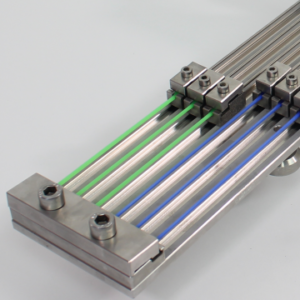

• Sample holder for the simultaneous test of 6 samples

• Pneumatic lifting system for the easy handling of the sample holder

• Windows bases software for TR test performance

The Sample Holder makes it possible to:

• Carry out simultaneous testing on 6 samples.

• Read automatically the retraction of each sample with 0.02 mm resolution

• Lock sample position in extended position during test preparation

• Automatically release of test samples at the end of the conditioning time.

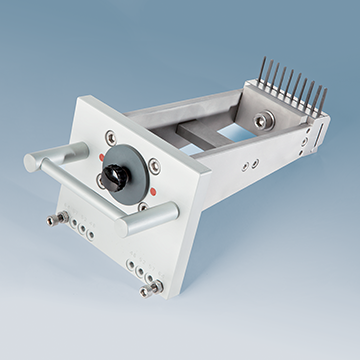

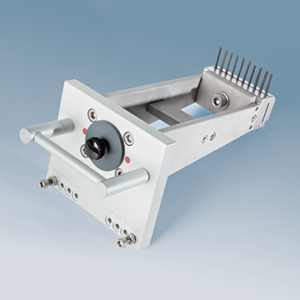

• Pneumatically actuated striker

• Sample holder for the simultaneous test of 10 samples

• Windows bases software for Brittleness Point test performance

• Datagest software for database management.

The striker is in compliance with international standards and the clearance can be set according to the kind of test (4.8, 5.2, 5.7, 6.4 mm). A pneumatic piston drives the striker and permits to perform the tests while the samples are immersed in the cooling liquid. A pressure regulator enables the speed of the striker to be adjusted in compliance with standards depending from the number of samples and the density of the cooling liquid in use.

The software permits to prepare and store test procedures with custom test conditions.

| Test temperature: | -120 to +20 °C (with liquid nitrogen tank) -70 to +20 °C (with refrigeration unit) |

| Data Output: | TR Test: TR10, TR30, TR50, TR70, TRx1 & TRx2 | Calculated TR points: t10, t30, t50, t70, tx1 & tx2 (tx1 / tx2 are user defined points) | Brittleness Point Test: Test temperature |

| Data Display: | % Retraction vs. Temperature Curves for each sample | Temperature vs. Time |

| Temperature Control: | PID with ± 0.1 Cº accuracy |

| Cooling System: | Liquid nitrogen with internal heat exchangers or refrigeration unit |

| Test Chamber: | 5 liter, 404 Stainless Steel with mixer |

| Test Bath: | Methyl Alcohol — Silicon Oil |

| Sample Holder: | TR—Test: 6 samples | Brittleness Point Test: 10 Samples |

| BP Test Striker: | Striker with automatic or manual start | Pressure regulator for pneumatic piston |

| Insertion/Extraction: | Pneumatic system for TR Test |

| Power: | 220 VAC, 50/60Hz, 1 PH |

| Power Consumption: | 750 Watt |

| Air Supply: | Min 6 bar (~87 psi), Filter/Regulator/Lubricator Required |

| Dimensions (W x D x H): | 700 x 710 x 1500 mm |

| Weight: | 120kg (264 lb.) |

TR Test, ASTM D2137, D2137, ASTM D746, D746, ISO 2921, ISO 812, DIN ISO 812, BS 903-A29, BS 903-A25, ASTM D1329, D1329, NF T4NF T46-032, brittleness, flexibility, low temperature, rubber-coated fabrics, retraction at low temperature, low temperature retraction, brittleness point, brittle failure, brittleness temperature, elastomer, impact, plastics, rubber property, crystallization, glass transition, first order phase transition, rubber, viscoelastic, coated fabric, flexible, polymer.