Nine distinct setups permit the testing of very delicate to extremely rigid materials. Taber Stiffness Testers will evaluate paper, foil, light metallic sheet, laminated plastic, cardboard, wire, and other flexible materials up to 5.5mm (0.219 inches) thick that do not exceed 10,000 Taber Stiffness Units.

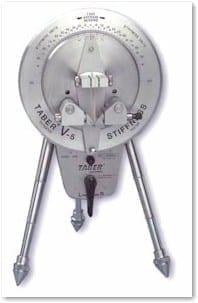

Based on the original Taber Stiffness Tester, Model 150-B offers telescoping tripod legs which make this instrument lightweight and portable. Operated manually by an lever control switch, a robust housing protects the electrical components. The new ratchet stop roller significantly reduces specimen mounting variability.

A Complete Data Sheet for the Taber® Stiffness Tester 150-B is available for download:

Ask for Price

Standard Components Model 150B:

- Compensator Range Weight

- Range Weight (500, 1000 and 2000 units)

- Range Weight Case

- Calibration Specimen

Standard Features Model 150B:

- Factory calibrated to accuracy of ±1% full scale

- Telescoping, tripod base

- Ratchet stop roller

- Constant speed motor

- Dynamic brake holds pendulum at the deflection

- Range weights to test most products

Model 150B Optional Accessories (sold separately):

- High Sensitivity Attachment

- Triple Cut Specimen Shear

- Calibration Specimens

- Auxiliary Range Weight Set (3000 and 5000 units)

- Wire/Tube Testing Apparatus

- Step-Down Transformer (required for 220V operation)

| SDO | Number | Title / Description |

| Appita | 1301.431RP | Stiffness of Paper and Paperboard Australian/New Zealand Standards series 1301, Methods of test for pulp and paper have been developed by the Appita Technical Committee and are published by Standards Australia and Standards New Zealand. |

| SAI | 1301.431RP | Methods of Test For Pulp and Paper — Taber Bending Resistance of Paper and Paperboard |

| ASTM | D5342 | Standard Test Method for Resistance to Bending, of Paper and Paperboard (Taber-Type Tester) |

| ASTM | D5650 | Standard Test Method for Resistance to Bending of Paper of Low Bending Stiffness (Taber-Type Tester in 0 - 10 Taber Stiffness Unit Configuration) |

| BSI | BS 3748 | Method for Determination of Resistance to Bending of Paper and Paper Board. |

| CPPS | D28P | Stiffness of Paper and Paperboard (Taber Method) |

| ISO | 2493 | Paper and Board — Determination of Resistance to Bending |

| JIS | P8125 | Testing Method for Stiffness of Paperboard by Bending Load |

| TAPPI | T 489 om4 | Bending Resistance (Stiffness) of Paper and Paperboard (Taber Type Stiffness Tester in Basic Configuration) |

| TAPPI | T 566 om2 | Bending Resistance (Stiffness) of Paper (Taber Type Tester in 0 — 10 Taber Stiffness Unit Configuration) |

| AENOR | UNE 57075 | Paper and Board, Determination of Resistance to Bending. |

Appita, 1301.43RP, SAI, ASTM, D5963, D5650, BSI, BS 3748, CPPS, D28P, ISO, 2493, ISO 2493, JIS, P8125, TAPPI, T 566 om2, T566, T 489 om4, T489, AENOR, UNE 57075, service life, service performance, Taber stiffness, Taber, stiffness, bending, resistance to bending, flexible paper, low grammage paper, paper, cardboard, paperboard, board, material stiffness, flexural strength, 85.060