CCSi features the Gibitre Automatic Hardness Check for evaluating the durometer hardness of elastomers and most polymers.

Stand-alone automatic hardness units are independent hardness measurement devices designed for the execution of hardness tests according to a specific hardness scale. The instruments have been designed to meet the requirements of research labs and for production control.

The solid construction of the instrument, the high quality sensors, and the lifting system with ball-recirculation screw makes them ideal both for research purposes and for heavy-duty production control.

Available ASTM D2240 hardness scales are: Shore A, B, C, D, DO, OO, and M

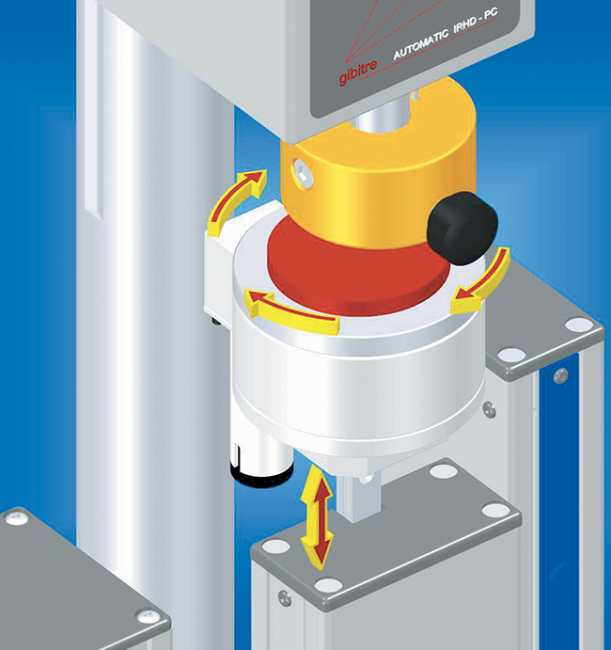

• Motor controlled displacement of the sample for automatic multiple testing

• The hardness units can be controlled both with Gibitre Hardness Software and with Gibitre Touch Screen display

• Full conformity with international standards

Accessories

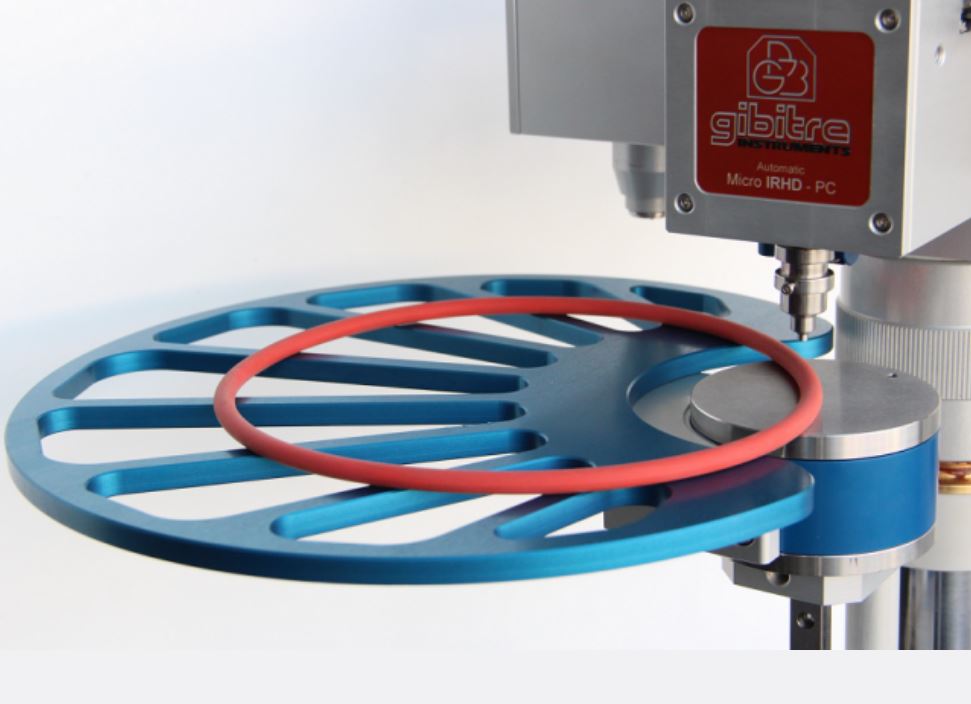

Extension plate for the testing of big parts.

Centering devices for O-rings.

Centering device for rubber hoses.

Gibitre Touch Screen display

Test modality: Fully automatic test in different points of the same sample

Test results calculated for each test:

ASTM D2240 units: Initial hardness, hardness values after set test times;

Resolution: 0.01 Hardness point

• Perform multiple tests automatically on the specimen

• Save all test results in the SQL database

• Compare the results with the tolerance limits

• Produce test reports

Ask for Price

| Applicable Standards: | ASTM D2240 |

| Test Types: | A, B, C, D, DO, OO, and M |

| Test Modality: | fully automatic, up to 5 determinations |

| Test Time: | standard test time (dwell) | user selectable test times |

| Test Data: | test & sample identification information | average of up to 5 determinations | standard deviation | mean | relaxation curves (during dwell time) nonconforming tests | may be repeated or excluded |

| Graphed Data: | relaxation curves (hardness variation during dwell) |

| Tabular Data: | | test & sample identification information | measurement determinations | standard deviation | mean | min/max tolerances |

| Test Resolution: | .01 durometer points |

| Tolerance Verification: | automatic comparison of user defined tolerances to actual test results |

| Calibration: | electronic calibration report with traceability to primary reference standard |

| Hardware: | Minimum Configuration: Intel Core i5 4 GB RAM. ; Connection to the instrument via USB Cable (included) |

| Software: | Windows 10 |

| Language Options: | English, German, Italian, French, Spanish |

| Power: | 110-240 V, 50/60 Hz, 15 W, single phase |

| Test Unit Weight: | 30 kg (67 lb.) |

| Test Unit Dimensions: | 250 x 250 x 600 mm (9.8 x 9.8 x 23.6 inches) |

IRHD Durometer, ISO 48, ASTM D1415, DIN 53519, international rubber hardness degrees, international hardness, differential penetration, hardness scale value, force, penetration depth, dimension ball, normal test, N, high hardness test, H, low hardness test, L, microtest, M, curved surface, CN, CH, CL, CM, Shore durometer, Shore hardness, Shore, hardness, rubber hardness, plastic, plastic hardness, indentation hardness, ebonite, ebonite hardness, rubber hardness testing, rubber testing, hardness testing, durometer hardness, testing, MIL-STD-45622A, MIL-I-45208A, 83.060, 83.080.01.