CCSi designs and manufactures high quality specimen cutting dies completely inhouse at our facility in Akron, OH. Our complete vertical integration allows CCSi to provide exceptional quality dies at competitive prices.

Our process starts with high, quality American made tool steel. We then grind, machine, harden, wire EDM, sharpen, and dimensionally certify the dies. The wire EDM manufacturing process creates perfectly vertical interior walls. This allows the die to be sharpened repeatedly without altering the dimensional characteristics of the sample and provides excellent long term value.

All CCSi dies come with the serial and model number laser engraved for easy identification. Also included is a rugged, foam lined carrying case for protection while the die is not in use.

Our standard dies have no adapters and are intended for use in a “clicker” style press.

These specimen dies are employed to prepare samples using a Mooney Viscometer, as described in ASTM D1646 ‘Standard Test Methods for Rubber — Viscosity, Stress Relaxation, and Pre-Vulcanization Characteristics (Mooney Viscometer)’:

- Mooney viscosity, the shearing torque resisting the rotation of a rotor, embedded in rubber, within a die cavity;

- stress relaxation, upon abruptly stopping the rotation of the rotor, the torque or stress, on the rotor decreases at a rate dependent on the rubber and the temperature of the test;

- pre-vulcanization, when compounded rubber is tested at a temperature at which vulcanization may occur, the vulcanization reaction produces an increase in torque.

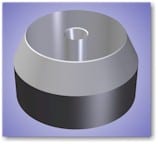

It is necessary for the Mooney Viscometer test specimens to be formed in two halves, as they act as an envelope in which the rotor is encapsulated. The lower specimen half requires a centrally located orifice through which the shaft of the rotor passes.

The upper specimen half is a solid disc, which under the pressure and temperature of the Mooney Viscometer die cavity, combines with the lower specimen half to form a homogenous capsule.

The combined volume of the two specimen halves is stipulated as 25 ± 3 cm3. The volume may be calculated as a function of the mass, provided the relative density is known. Therefore, it is necessary to first determine the density of the subject material, then adjust the mass accordingly (± 3 g) after the specimens are die cut.

Options include:

- ISO-17025 Certification

- Arbor Press Adapter (post type, dimensions to be specified at purchase)

- Mallet Handle

- NAEF brackets and ejectors

- Custom brackets and adapters

$980.00

specimen dies, cutting dies, Standard Test Methods for Rubber – Viscosity Stress Relaxation and Pre-Vulcanization Characteristics (Mooney Viscometer), ASTM D1646, D1646, curing characteristics, Mooney, viscometer, rheology, stress relaxation, viscosity, shear, scorch, scorch test, vulcanization characteristics, shearing torque.