CCSi designs and manufactures high quality specimen cutting dies completely inhouse at our facility in Akron, OH. Our complete vertical integration allows CCSi to provide exceptional quality dies at competitive prices.

Our process starts with high, quality American made tool steel. We then grind, machine, harden, wire EDM, sharpen, and dimensionally certify the dies. The wire EDM manufacturing process creates perfectly vertical interior walls. This allows the die to be sharpened repeatedly without altering the dimensional characteristics of the sample and provides excellent long term value.

All CCSi dies come with the serial and model number laser engraved for easy identification. Also included is a rugged, foam lined carrying case for protection while the die is not in use.

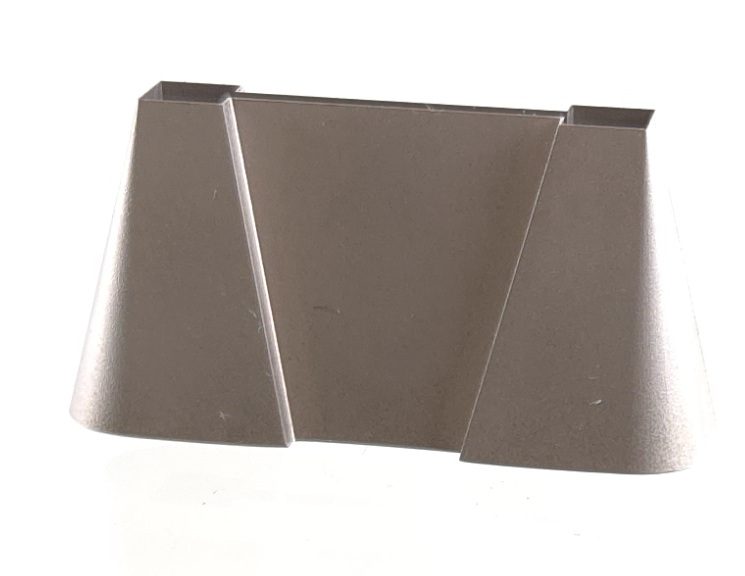

Our standard dies have no adapters and are intended for use in a “clicker” style press.

CCSi manufactures these high quality Specimen Cutting Dies for the determination of the Temperature Retraction (TR) for the evaluation of the effects of crystallization and for the comparison of the viscoelastic properties of rubber and rubber-like materials at low temperatures, as described in ASTM D1329, “Standard Test Method for Evaluating Rubber Property—Retraction at Lower Temperatures (TR Test).”

This test method is carried out by:

- elongating the specimen;

- locking it in the elongated condition;

- “freezing” it to a state of reduced elasticity;

- releasing the specimen and allowing it to retract freely while raising the temperature at a uniform rate;

- measuring the length of the specimen at regular temperature intervals while it is retracting;

- computing the percentage retraction at the temperature intervals.

Three die lengths (the narrow rectangular portion) are specified in the method: 25, 38, and 51 mm, while the end “tabs” are all of the same dimensions. These are used according to the ultimate elongation and the limitations of the specimen racks.

In practice, the temperatures corresponding to 10% (TR10) and 70% (TR70) retraction are of particular importance.

The difference in the temperature between 10% retraction and 70% retraction increases correspondingly to an increase in crystallization. Where TR70 correlates with low-temperature compression set, TR10 correlates with brittleness points in vulcanizates with similar polymers. The retraction rate correlates with low temperature flexibility of both crystallizable and non-crystallizable rubbers.

This test provides for the evaluation of the effect of crystallization and comparing viscoelastic properties of materials at low temperatures. When employed in conjunction with other low temperature tests, it is very useful in selecting materials for low temperature applications.

Options include:

- ISO-17025 Certification

- Arbor Press Adapter (post type, dimensions to be specified at purchase)

- Mallet Handle

- NAEF brackets and ejectors

- Custom brackets and adapters

$825.00

specimen dies, ASTM D1329 Specimen Cutting Dies, TR, TR test, cutting dies, Standard Test Method for Evaluating Rubber Property—Retraction at Lower Temperatures (TR Test), D1329, ASTM D1329, subnormal temperature, low temperature, temperature retraction, brittleness, brittleness point, cold test.