CCSi designs and manufactures high quality specimen cutting dies completely inhouse at our facility in Akron, OH. Our complete vertical integration allows CCSi to provide exceptional quality dies at competitive prices.

Our process starts with high, quality American made tool steel. We then grind, machine, harden, wire EDM, sharpen, and dimensionally certify the dies. The wire EDM manufacturing process creates perfectly vertical interior walls. This allows the die to be sharpened repeatedly without altering the dimensional characteristics of the sample and provides excellent long term value.

All CCSi dies come with the serial and model number laser engraved for easy identification. Also included is a rugged, foam lined carrying case for protection while the die is not in use.

Our standard dies have no adapters and are intended for use in a “clicker” style press.

CCSi ASTM D624-A dies are built to the standard (inch) specification. If a metric (mm) is required it must be requested.

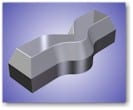

Tear Die A is a specimen, in a crescent shape, which is nicked by a razor. The force acts along the major axis, perpendicular to the nick and measures tear propagation.

This model DOES NOT include the integral nicker. The nick can be applied with a razor or our specimen nicking apparatus.

For D624-A with integral specimen nicker click here.

Options include:

- ISO-17025 Certification

- Arbor Press Adapter (post type, dimensions to be specified at purchase)

- Mallet Handle

- NAEF brackets and ejectors

- Custom brackets and adapters

$830.00

specimen dies, cutting dies, tensile, tear, tear strength, Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers, tear resistance, tear propagation, nicked tear specimen, trouser tear, tear die, tensile tear, tensile tear die, constrained path tear, ASTM D624, D624, ISO 34:1, ISO 34, ISO/34.