CCSi designs and manufactures high quality specimen cutting dies completely inhouse at our facility in Akron, OH. Our complete vertical integration allows CCSi to provide exceptional quality dies at competitive prices.

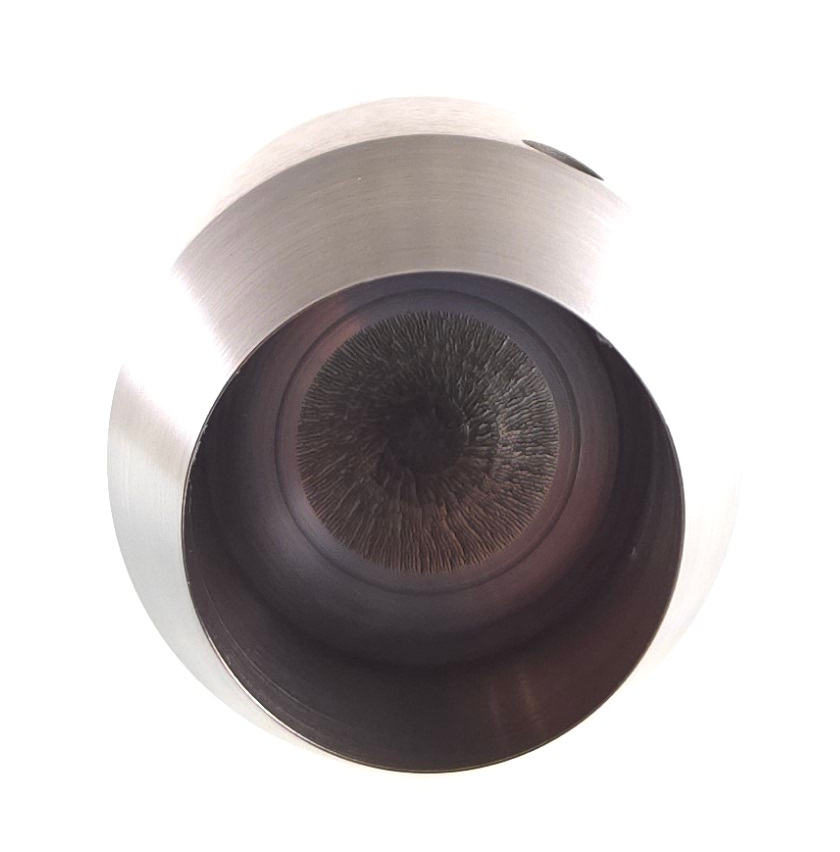

Our process starts with high, quality American made tool steel. We then grind, machine, harden, wire EDM, sharpen, and dimensionally certify the dies. The wire EDM manufacturing process creates perfectly vertical interior walls. This allows the die to be sharpened repeatedly without altering the dimensional characteristics of the sample and provides excellent long term value.

All CCSi dies come with the serial and model number laser engraved for easy identification. Also included is a rugged, foam lined carrying case for protection while the die is not in use.

CCSi manufactures high quality Specimen Cutting Dies for the determination of compression set, under constant force or constant deflection, as indicated in ASTM D395 ‘Standard Test Methods for Rubber Property — Compression Set’.

The Type 1 specimen die is used in both ASTM D395 ‘Test Method A’ and ‘Test Method B’, while the Type 2 specimen die is used solely for ‘Test Method B’.

While most CCSi cutting dies are available with mallet handles, arbor press mounts, or press adapters, the ASTM D395 specimen cutting dies are equipped with a special integral 0.375 inch diameter shaft. This facilitates mounting in a drill press, or similar device, as it is necessary to rotate the die while cutting the specimen.

ASTM D395-T1 29.0 ± 0.5 mm (1.140 ± 0.020 inch) Ø

Ask for Price

specimen dies, cutting dies, Type 1, Type 2, Standard Test Methods for Rubber Property – Compression Set, ASTM D395, Method B, deformation, deflection, compression, elastic property, hysteresis, recovery, compressive force, constant force, low temperature.