The Gibitre™ TCS features:

- Automatic detection of the load cell installed;

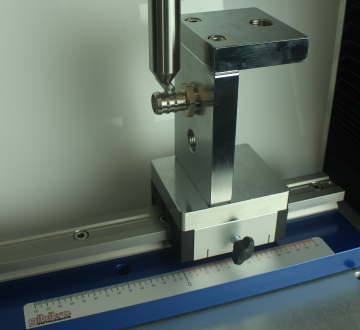

- 5 kN load cell operating in traction and compression (standard version);

- Measurement of the crosshead position with 0.0025 mm resolution;

- Adjustable speed from 2 to 1000 mm/min;

- Safety limit switch for adjustment of the slide stroke and automatic return on termination of the test;

- Protection hatch.

Ask for Price

The Gibitre™ TCS optional features include:

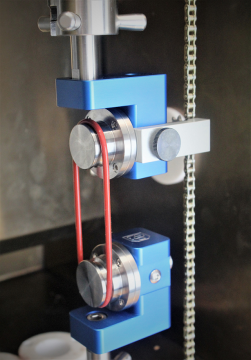

- Stretch gauge for differential extension measurement with resolution 0.01 mm;

- Wide range of load cells operating in traction and compression up to 10 kN ;

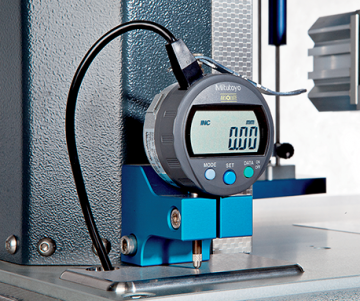

- Thickness gauge for direct acquisition of sample thickness;

- Pneumatics grips with regulation of closure pressure;

- Wide range of grips for traction, compression, peeling, stress relaxation tests for standard or customer defined tests;

- Support stand for instrument and PC.

The software includes a wide range of predefined test procedures in compliance with international standards (traction, compression, peeling, hysteresis, flexion, etc.) and the option of creating fully personalized test procedures for nonstandard tests.

Direct sample thickness acquisition from the optional digital thickness gage performs automatic calculation of the cross-section depending on the type of sample selected, which reduces test times and the possibility of operator introduced error.

Display and printing in different colors of the relative test curves affords rapid and simplified test identification, while the automatic, real-time, assessment of compliance with tolerance limits and predefined relative statistical elaboration (average, median, standard deviation, max, min, Cp and Cpk) virtually automated the testing process!

The automatic generation of tolerance limits produced from the acquired statistics (average and standard deviation) of historical data further uncomplicates the SPC web.

The Gibitre™ Tension / Compression System (TCS) also features computerized calibration and diagnostics… assuring ongoing precision and accuracy.

| Standards: | · ASTM D412, D624, D575, D790 · DIN 53 504, 53 515 & 53 507 · ISO 34, 37, 816, 2285, 2411, 3384-B |

| Test Types: | · traction · compression · tear · hysteresis · peel · relaxation · flexation |

| Test Procedures: | · tension · compression |

| Numerical Test Data: | · force · elongation · stress · strain · tear strength · hysteresis at specified conditions: max, min, break, defined stress, defined strain, defined time |

| Data Analysis: | · tolerance limits · relative statistics: average, median, standard deviation, max, min, Cp & Cpk |

| Transducer/Load Cell: | · 10 kN maximum · automatic load cell detection |

| Load Cell Accuracy | · 0.5 % max error throughout range · precision in compliance with ASTM E4 |

| Elongation Measurement: | · differential (0.01 mm resolution w/ extensometers) · absolute (0.0025 mm resolution w/ crosshead) · compliance with ASTM E83 Class E |

| Calibration: | · certified with reference to primary standards |

| Graphical Representation: | · Y axis: absolute load, load/cross section, load/thickness · X axis: differential elongation, absolute elongation, time |

| Measurement Units: | · N · N/mm · N/mm² (mPa) · kgf · kgf/mm · kgf/mm² · psi |

| Crosshead: | · speed: 2 — 1000 mm/min · stroke: 950 mm |

| Thickness Measurement: | · digital thickness gage (optional) |

| Power Supply: | · 220 VAC ± 10% · 50 Hz ± 3 · 4 Ampere · single phase — other on request |

| Air Pressure: | · 6 bar (600 kPa / 87.02 psi) for pneumatics grips |

| Dimensions (W x D x H): | · 600 x 700 x 1800 mm (23.6 x 27.6 x 70.9 inch) |

| Weight: | · 80 kg (176.4 lb) |

| Power Required: | · 500 Watts |

material testing systems, tensile testing machine, universal testing machine, tensile tester, universal tester, compression test, tensile, tear, tension, tensile set, dumbbell, tensile stress, tensile strength, yield point, ASTM D412, D412, set after break, set-after-break, ring tensile test, elongation, tensile properties, ASTM D624, D624, ISO 1798, ISO 34, rubber articles, rubber products.