Utilizing a proprietary metal oxide catalyst, the CDU is able to achieve over 99% destruct efficiency for concentrations of up to 250 PPHM. Comparatively, alternative technologies that employ activated carbon, which chemically reacts with the ozone, generates carbon dioxide and small amounts of carbon monoxide.

Another disadvantage of this process is that it consumes the activated carbon!

Unlike activated carbon, which requires frequent replacement, the OREC™ CDU Catalyst is not rapidly diminished by ozone.

Additionally, the destruction of ozone in the OREC™ CDU takes approximately 20% of the time required by activated carbon technologies.

The Catalytic Destruct Unit is constructed of high—grade stainless steel. It rests on 4 highly ozone resistant elastomeric supports which ensures stability and reduces the effects of vibration.

The CDU is coated with an industrial epoxy based finish which is color matched to the OREC™ Chambers. A stainless steel mesh screen covers the exhaust port preventing entry of foreign material. The CDU is internally sealed for maximum efficiency.

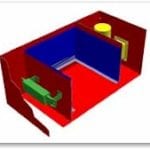

The illustration shows a cut—away view of the Catalytic Destruct Unit. The primary structural pieces are shown in red, while green represents the heater and heater support brackets. The metal oxide catalyst is contained within the blue structure and yellow identifies the blower. The ozone laden air enters through the opening in the bottom just below the heater.

Ask for Price

Ozone laden air enters the process through an opening on the bottom of the unit. The blower intakes fresh air at a rate approximately 5 times of the chamber exhaust volume, generating a low pressure area above the chamber exhaust port. The fresh air / ozonated exhaust mixture is then passed through a heating chamber to reduce ambient moisture, dramatically increasing catalyst efficiency.

The heated fresh air / ozonated air mixture is routed downward through a filtration system, preventing airborne particulates from entering the process, then drawn through the catalytic chamber. It is at this point that the ozone is catalyzed.

The de—ozonated air then enters the blower and is finally exhausted into the atmosphere. Flow rate, flow direction, chamber configuration, and catalytic chamber volume have all been carefully designed and tested to provide maximum residence time, thus high efficiency. The “S” shaped flow pattern reduces the overall size of the CDU, making it the most compact available at the efficiency level.

| Current EPA 1-Hour Standard: | 0.12 PPM |

| Proposed EPA 8-Hour Standard: | 0.08 PPM |

| OSHA 8-Hour Standard: | 0.10 PPM |

| Perceivable Through Smell | 0.03 PPM |

| Probability of Headaches | 0.10 PPM |

| Lung Function Impairment | 0.16 — 0.20 PPM |

| Reduced Physical Strength | 0.24 — 0.70 PPM |

| Inflammatory Reaction of Tissue | 0.80 PPM |

| Chromosome Damage Begins After 6 — 10 Hours | 1.00 PPM |

| Model Number: | ODU-120 & ODU-240 |

| Full Operation Range: | 0-250 PPHM |

| Efficiency: | > 99% |

| Air Flow: | 140 CFM |

| Heater Energy: | 500 Watt |

| Catalyst Life: | 18 — 24 Months |

| Catalyst Volume: | 0.5 Ft³ |

| Catalyst Mass: | 12.5 kg (27.6 lb) |

| Total Unit Weight: | 27.2 kg (60 lb) |

| Dimensions* (W x D x H): | 682.60 x 355.6 x 287.35 mm (26.874 x 14 x 11.313 in.) |

| Power Requirements: | 120/240 VAC, 60 Hz, 1 P |

| Warranty: | 1 Year Parts/Workmanship |

* Dimensions include mounting feet and handle

OREC, Ozone Research Equipment Company, 0500, 0900, ozone test chambers, ozone, ozone destruction, ozone generation, ozonator, ozone generator, ozone test chamber, ozone monitor, Osmonics, ASTM D518, ASTM D1149, ASTM D1171, ASTM D3395, ASTM D4575, ASTM D470, ISO 1431, ozone research, rubber cracking, ozone resistance, rubber, crack growth, weathering, rubber deterioration, surface cracking, ozone cracking, ozone measurement, rubber test, ultraviolet, UV, 0550, 0950, ODU-120, ODU-240.