The Barcol Impressor is a convenient tool for testing the hardness of aluminum, aluminum alloys, copper and brass as described in ASTM B648 Standard Test Method for Indentation Hardness of Aluminum Alloys by Means of a Barcol Impressor.

It is also particularly well suited for other materials including plastics and fiberglass as described in ASTM D2583 Standard Test Method for Indentation Hardness of Rigid Plastics by Means of a Barcol Impressor. The instrument is designed for use on fabricated parts, assemblies, as well as unprocessed materials.

The Barcol Impressor can be used in any position, in any space that will allow for the operator’s hand, and does not require that the user be experienced! The Barcol hardness reading is indicated on the analog dial, displayed in equal graduations of 0 — 100.

The test determinations are instantaneous… there is no need for preloading, or multiple measurements! The Barcol Impressor weighs only 510.3 grams (18 ounces) and comes complete with carrying case, adjusting wrench, two spare indenters, and two test discs for state-of-calibration assurance.

Ask for Price

The Barcol Impressor is best suited for testing homogeneous materials. Material of granular, fibrous or coarse structure will produce a wide variation in hardness readings because of the small diameter of the indenter point.

In order to obtain accurate test determinations the material should be at least 1/32 inch (0.8 mm) thick and large enough for a minimum distance of 1/8 inch (3.175 mm) in any direction from the indenter point to the edge of the specimen.

The testing area should be smooth and free from mechanical damage. Simply exert a light pressure against the instrument to drive the spring—loaded indenter into the material.

The indenter must be perpendicular to the surface being tested. On very soft metal, the highest reading should be used since cold flow permits the spring—loaded indenter to continue penetration.

The physical characteristics of very soft materials are such that correlation between different hardness measuring systems cannot be established. Therefore, no conversions are offered for the 935 and 936 models. The hardness limits for each material should be established empirically.

Model GYZJ—934—1: for fiberglass, soft metals such as aluminum, aluminum alloys, brass, copper, and some harder plastics and fiberglass.

· Approximate range of 25 to 150 Brinell (10 mm ball, 500 KG load).

· This Model fulfills the requirements of ASTM D2583 and B648.

Model GYZJ—934—2: a variation of the 934—1 that has a ‘flat bottom’ shaped support leg. This is designed for application to a ladder rung. It is approved by the National Fire Protection Agency (NFPA).

Barcol Magazine AdBarcol Impressor Magazine Ad

Barcol Magazine AdBarcol Impressor Magazine Ad

Model GYZJ—935: for soft plastics and soft metals.

· Approximate range of 50 to 110 Rockwell ‘R’.

Model GYZJ—936: for extremely soft materials such as lead, linoleum and leather.

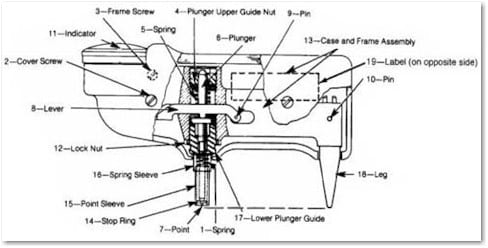

| Model | GYZJ-934-1 | GYZJ-934-2 | GYZJ-935 | GYZJ-936 | Description | Quantity |

| 1 | AYRS-62 | AYRS-62 | AYRS-62 | AYRS-62 | Spring | 1 |

| 2 | BYRF-3114 | BYRF-3114 | BYRF-3114 | BYRF-3114 | Cover Screw | 2 |

| 3 | BYRF-250 | BYRF-250 | BYRF-250 | BYRF-250 | Frame Screw | 1 |

| 4 | GYZJ-2 | GYZJ-2 | GYZJ-2 | GYZJ-2 | Plunger Upper Guide Nut | 1 |

| 5 | GYZJ-3 | GYZJ-3 | AYRS-146-1 | AYRS-146-1 | Spring | 1 |

| 6 | GYZJ-4-1 | GYZJ-4-1 | GYZJ-4-1 | GYZJ-4-1 | Plunger | 1 |

| 7 | GYZJ-6-5 | GYZJ-6-5 | GYZJ-6-5 | GYZJ-67 | Indenter Point | 1 |

| 8 | GYZJ-7 | GYZJ-7 | GYZJ-7 | GYZJ-7 | Lever | 1 |

| 9 | GYZJ-8 | GYZJ-8 | GYZJ-8 | GYZJ-8 | Pin | 1 |

| 10 | DYRA-218 | DYRA-218 | DYRA-218 | DYRA-218 | Pin | 1 |

| 11 | GYZJ-15-2 | GYZJ-15-2 | GYZJ-15-2 | GYZJ-15-2 | Indicator | 1 |

| 12 | GYZJ-16 | GYZJ-16 | GYZJ-16 | GYZJ-16 | Lock Nut | 1 |

| 13 | GYZJ-23-1 | GYZJ-23-1 | GYZJ-23-1 | GYZJ-23-1 | Case & Frame Assembly | 1 |

| 14 | GYZJ-61 | GYZJ-61 | GYZJ-61 | GYZJ-61 | Stop Ring | 1 |

| 15 | GYZJ-62 | GYZJ-62 | GYZJ-62 | GYZJ-62 | Point Sleeve | 1 |

| 16 | GYZJ-63 | GYZJ-63 | GYZJ-63 | GYZJ-63 | Spring Sleeve | 1 |

| 17 | GYZJ-64 | GYZJ-64 | GYZJ-64 | GYZJ-71 | Lower Plunger Guide | 1 |

| 18 | GYZJ-65 | GYZJ-64 | GYZJ-65 | GYZJ-65 | Support Leg | 1 |

| 19 | GYZJ-79-1 | GYZJ-79-SP | GYZJ-79-2 | GYZJ-79-3 | Label | 1 |

| — | GYZJ-17 | GYZJ-17 | GYZJ-17 | GYZJ-17 | Wrench | 1 |

| — | GYZJ-19-2 | GYZJ-19-2 | GYZJ-19-2 | GYZJ-19-2 | Storage Case | 1 |

| — | GYZJ-250 | GYZJ-250 | GYZJ-69 | GYZJ-70 | Test Block | 1 |

| — | GYZJ-78 | GYZJ-78 | — | — | Test Block | 1 |

| — | GYZJ-250-CS | GYZJ-250-CS | GYZJ-69-CS | GYZJ-70-CS | Calibrated Test Blocks | 5 |

Barber Colman, Barber-Colman, Barcol Impressor ,Barcol, Impressor, ASTM D2583, D2583, ASTM B648, B648, Materials Hardness Testing, fiberglass, aluminum alloys, aluminum, al, Barcol impressor test, hardness, hardness tests, indentation hardness, test by Barcol impressor, NFPA, National Fire Protection Agency, Standard Test Method for Indentation Hardness of Aluminum Alloys by Means of a Barcol Impressor, 77.120.10, Standard Test Method for Indentation Hardness of Rigid Plastics by Means of a Barcol Impressor, 83.080.01, 934-1, 935.