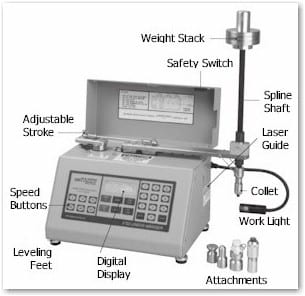

CCSi is pleased to introduce the Taber® Linear Abraser… the first wear and scratch tester specifically designed for measuring the abrasion resistance of finished products of virtually any size or shape!

The new Linear Abraser uses a floating head to follow the contours of the specimen, permitting the testing of finished products.

The limitations of specimen size and shape are virtually nonexistent, making the Linear Abraser ideal for testing molded plastic parts, automotive components, painted and coated parts, optical products… the possibilities are endless!

The Wearaser™ abrasive, similar in configuration to a standard pencil eraser, employs the same high quality materials found in other Taber® Abrasive Media, assuring consistent test results.

The Model 5750 features adjustable stroke length, speed, load, and a wide variety of Taber® Wearaser™ abrading media, allowing the customization of test parameters to suit virtually any requirement.

The optional sample tables provide additional flexibility for small or irregularly shaped specimens. Other optional attachments allow the conversion of the Linear Abraser to a scratch tester or a crock meter.

Please submit a Request for Quotation (RFQ) for the Taber Linear Abraser and any accessory or replacement items. Refer below to a description of the standard and optional components.

The included Adobe® Portable Document File (PDF) contains the Taber® Linear Abraser Model 5750 Set-Up chart. It is provided to assist in establishing specific test loads for the Model 5750:

Taber® Linear Abraser Model 5750 Set-Up Chart

Complete Data Sheets for Taber® Abraser Model 5750:

Ask for Price

- Variable Stroke Lengths of 0.5, 1.0, 2.0, 3.0 & 4.0 inches;

• Other stroke lengths are available. - CS—10 Calibrase® and H—18 Calibrade® Wearasers™ are included;

• Customized Taber® abradants are also available. - Variable Stroke Speeds of 2, 15, 25, 40 & 60 cycles per minute;

- Variable Load from 350—1100 g in 250 g increments;

• Additional weight discs are available to increase the load to 1600 g. - Standard Attachment for Wearaser™ abrasive media;

- 115 / 230 VAC Switchable Power Supply,

- CE Marked.

The linear motion arm has an adjustable stroke length, variable to accommodate virtually any required contact surface area of a test specimen. The precision bearing on the splined shaft allows the abrading head to ‘float’, freely following the specimen surface whether contoured, irregular, or flat.

The test parameters are stroke length, speed, load, and number of test cycles; each of which can be altered to simulate actual use conditions, establish QC control limits, QA guidelines, or for empirical study

can be altered to simulate actual use conditions, establish QC control limits, QA guidelines, or for empirical study.

The test counter is programmable from 1—999,999 test cycles. It features an LCD back lit display for improved visibility.

There are two user selectable modes: RUN, for performing tests, and REFACE, which allows for the refacing of the abradant without having to reprogram the number of cycles.

| Description | Quantity |

| Wearaser™ Abrading Head & Splined Shaft (350 g) | 1 |

| Wearaser™ Depth Gauge Tool | 3 |

| Weights, 250 g | 10 |

| CS—10 Wearaser™ Abrasive Media | 10 |

| H—18 Wearaser™ Abrasive Media | 1 |

| Electrical Cord (115 VAC) | 1 |

| Electrical Cord (230 VAC) | 1 |

| Hex Key Tool | 1 |

| Hand Brush | 1 |

Scratch Kit [P/N 130575]

The Scratch Kit allows you to perform single pass or multiple pass scratch testing. Included are a 7x measuring magnifier, the attachment, and two conical diamond tools:

- Model 139—55 with 90°, 3 mil, radius point;

- Model 139—56 with 90°, 3.5 mil, radius point.

The diamond scratch tool, Model 139—159 is also available, and sold separately. The Model 139—159 features a cutting edge that is the converging point from three sides and edges of a perfect cube.

Also available are:

- 139—55 Replacement Conical Diamond Tool [P/N 121006];

- 139—56 Replacement Conical Diamond Tool [P/N 121006—1];

- 139—58 Diamond Scratch Tool [P/N 121008].

Universal Kit [P/N 130572]

This attachment allows the simulation of actual use conditions. The performance of ‘real world’ testing is accomplished using your abradant material, or one of the many Taber® abradants. The Universal Kit is ideal for testing on flat surfaces.

Crock Meter Kit [P/N 130570]

The Crock Meter Kit is typically used to evaluate color fastness (transfer) on textiles, cellulose fiber derivatives, and other materials. The kit includes a 0.625 inch (15.875 mm) acrylic ‘finger’, clamp ring, and package of crocking cloths.

Also available are:

- Replacement Acrylic Crock Finger [P/N 130818];

- Replacement Crocking Cloths [P/N 130811].

Flat Specimen Table [P/N 130809]

A critical aspect in testing with the Taber® Linear Abraser is securing the specimen during the test. The flat table (shown on the left) is designed for rigid, flat specimens. They are mounted to the table using four adjustable mounting brackets. A leveling bubble and adjustable table supports are used to assure that the table surface is parallel to the work area.

Specimen Tables of many other configurations are available, or can be manufactured to suit a specific application.

Universal Specimen Table [P/N 131734]

The PanaVise® flexible mounting system enables the testing of all shapes and sizes of specimens. The PanaVise® is attached to the Linear Abraser to ensure a stable test platform. A low profile mount includes the patented ‘split ball’ design, allowing the vise head to be positioned on the x, y and z axis. The specimen can be tilted, turned or rotated to accommodate virtually any specimen configuration. Included are the base mount; low profile base; three interchangeable heads (vise head, flat table, wide jaw vise); and spacer.

- Standard Grip Head for the Universal Specimen Table [P/N 131724]

The nylon jaws of the Standard Head for the Universal Specimen Table open 2¼ inches (57.1 mm). The firm grip provides secure support. It is designed to avoid undue stress and strain on the specimen, providing reproducible and repeatable test determinations.

Wide Grip Head for the Universal Specimen Table

The ribbed, neoprene pads are reversible. The flat surface firmly secures standard specimens, while the reverse side ‘V’ holds cylindrically or spherically shaped test pieces. The jaws open to a full 6 inches (152.4 mm).

Fixturing Head for the Universal Specimen Table [P/N 131725]

The flat surface of this flexible fixture is 5.375 inches (136.5 mm) in diameter. Six slots and six ¼ inch (6.35 mm) holes, permit specimens to be attached easily.

Vacuum Vise [P/N 131062]

This versatile attachment has adjustable jaws that open a full 2½ inches (63.5 mm) to accommodate contoured specimens or custom fixtures. An integral vacuum base locks the vise to the work surface.

45º Vacuum Vise [P/N 131063]

The adjustable clamping jaws open to nearly 6 inches (152.4 mm) and can be pivoted at an angle of up to 45º. An integral vacuum base locks the vise to the work surface.

Splined Shafts

The standard 10 mm Ø splined shaft is 300 mm in length and has a maximum load of 1,600 g (1.6 kg). It is recommended to use the either the splined shaft of 250 mm in length or of 200 mm in length for heavier loads.

When tests require a lighter load, the splined shaft which is 8 mm Ø and 150 mm in length is recommended. An adaptor is included to mount this shaft in place of the standard shaft.

- 300 mm Spline Kit [P/N 132190] includes 85 g aluminum spline shaft (10 mm Ø x 300 mm) and bearing, used after S/N 20031338. Requires the use weight support [P/N 132212] for base load of 350 g;

- Weight Support [P/N 132212] for 350 g base load on (10 mm Ø x 300 mm) aluminum spline shaft [P/N 132190];

- 300 mm Spline Kit [P/N 130855] includes 180 g stainless steel spline shaft (10 mm Ø x 300 mm) and bearing, used after S/N 20031338. Requires the use weight support [130552] for base load of 350 g;

- Weight Support [P/N 130552] for 350 g base load on (10 mm Ø x 300 mm) stainless steel spline shaft [P/N 130855];

150 mm Spline Kit [P/N 132280] includes 43 g aluminum spline shaft (10 mm Ø x 150 mm) and bearing; - Adaptor Sleeve [P/N 131854] reduces standard holder opening of 10 mm to 8 mm for use with light weight spline kit;

- 150 mm Spline Kit [P/N 131603] includes 58 g (8 mm Ø x 150 mm) spline shaft, bearing, spline nut adaptor, accessory weight holder, 72 g [P/N 130552], adaptor sleeve [P/N 131854];

- Multiple Head Attachment [P/N 131877] includes dual load arm attachment, 300 mm spline kit [P/N 132190], weight support [P/N 132181], stainless steel Wearaser collet kit [P/N 130852).

Weight Discs

The standard minimum load for the Linear Abraser is 350 g. Using the three 250 g weight discs that are included, the load can be increased to 1,100 g (1.1 kg). Additional 250 g weight discs [P/N 130285] are available to increase the load to the maximum allowable 1,600 g (1.6 kg).

If an application requires greater incremental flexibility, additional weights are available:

- 10 g weight disc [P/N 132716];

- 20 g weight disc [P/N 132717];

- 50 g weight disc [P/N 131548];

- 75 g weight disc [P/N 131611];

- 100 g weight disc [P/N 131612];

- 150 g weight disc [P/N 131373];

- 200 g weight disc [P/N 130285];

- Precision Weight Kit [P/N 132739] spline shaft mounting of small weights without using weight support;

- Precision Weight Kit [P/N 132710] spline shaft mounting of small weights using weight support;

Wearaser™ Collet Kit [P/N 130852]

This is the standard stainless steel collet that comes with the Linear Abraser. It is used for a wide variety of abrasion tests. The opening accepts the ¼ inch (6.35 mm) Wearaser™.

- Wearaser™ Collet Kit [P/N 131852] (aluminum)

- Wearaser™ Collet Kit [P/N 131852] (plastic)

- Jumbo Wearaser™ Collet Kit [P/N 131852]

This is the larger optional stainless steel collet. It is used for a wide variety of abrasion tests. The opening accepts the jumbo ½ inch (12.7 mm) Wearaser™. - 45º Slotted Holder [P/N 131716-1] for use with collet kits;

- 60º Slotted Holder [P/N 131716-2] for use with collet kits;

- 75º Slotted Holder [P/N 131716-2] for use with collet kits;

- Special Holder [P/N 132735] for use with collet kits, has an adjustable angle of up to 180º.

Wearaser™

The Taber® Linear Abraser is equipped to accept the Wearaser™, Jumbo Weareraser™, and WearDisc™ abrasive media. It is made from the same abrasive material as the world famous Taber® Calibrase® and Calibrade® Wheels. The Wearaser™ abradants are available in a variety of levels of abrasiveness to suit virtually any application!

Calibrase® — a resilient material composed of rubber and aluminum oxide abrasive particles:

- CS—10F Wearaser™ [P/N 130684]: very mild abrasive action;

- CS—10 Wearaser™ [P/N 130685]: mild abrasive action;

- CS—17 Wearaser™ [P/N 130686]: harsh abrasive action.

- CS—10F Jumbo Wearaser™ [P/N 132075]: very mild abrasive action;

- CS—10 Jumbo Wearaser™ [P/N 132076]: mild abrasive action;

- CS—17 Jumbo Wearaser™ [P/N 132077]: harsh abrasive action;

- CS—10F WearDisc™ [P/N 131433]: very mild abrasive action;

- CS—10 WearDisc™ [P/N 131434]: mild abrasive action;

- CS—10 WearDisc™ [P/N 131435]: harsh abrasive action.

Calibrade® — a non-resilient material composed of vitrified (stone) and silicon carbide or aluminum oxide abrasive particles:

- H—10 Wearaser™ [P/N 130694]: fine abrasive action;

- H—18 Wearaser™ [P/N 130681]: medium abrasive action;

- H—22 Wearaser™ [P/N 130682]: coarse abrasive action.

- CS—5 Jumbo Wearaser™ [P/N 132648]: very mild abrasive action;

- H—18 Jumbo Wearaser™ [P/N 132078]: medium abrasive action;

- H—22 Jumbo Wearaser™ [P/N 132079]: coarse abrasive action;

- H—18 WearDisc™ [P/N 131400]: medium abrasive action;

- H—22 WearDisc™ [P/N 131401]: coarse abrasive action.

WearDisc™ Adhesive is a pressure sensitive adhesive discs used for attaching WearDiscs™ or other materials to the Universal Attachment:

- WearDisc™ Adhesive [P/N 132654]: adhesive discs.

Wearaser™, Jumbo Wearaser™, and WearDisc™ refacing strips for Calibrase® media:

- Refacing Medium [P/N 130687]: S—14 refacing strips.

Wearaser™ Depth Gage / Sharpener is used to set Wearaser depth and reface / chamfer vitrified Wearasers™:

- Depth Gauge [P/N 130695]: for use with ¼ inch Wearaser™.

| ASTM | D2197 | Test Method for Adhesion of Organic Coatings by Scrape Abrasion |

| ASTM | D5178 | Standard Test Method for Mar Resistance of Organic Coatings |

| ASTM | D6279 | Test Method for Rub Abrasion Mar Resistance of High Gloss Coatings |

| ASTM | F1319 | Standard Test Method for Determination of Abrasion and Smudge Resistance of Images Produced from Business Copy Products (Crockmeter Method) |

| AATCC | Method 8 | Colorfastness to Crocking |

| ISO | 105-X12 | Textiles - Tests for Colour Fastness, Part X12: Colour Fastness to Rubbing |

| ISO | 6722 | Road Vehicles - 60 V and 600 V Single Core Cables - Dimensions, Test Methods and Requirements |

ASTM, D2197, adhesion, balanced beam, scrape adhesion, tester, scrape, 25.220.60, scrape abrasion, D5178, mar resistance, balanced beam scrape adhesion, mar tester, balanced beam tester, coatings, mar, organic mar resistance, D6279, aluminum, coatings, gloss, wet rub, dry rub, D6037, grit, powder, rub test, scratch, 25.220.99, F1319, copying, crockmeter, crock meter, crocking, impact printers, inked ribbons, MICR, non-impact printers, OCR, smudge resistance, thermal transfer ribbons, toner images, AATCC Method 8, AATCC, Method 8, ISO 105-X12, ISO, 105-X12, 59.080.01, colour fastness to rubbing, colour fastness, colourfast, rubbing, rub test, color fast, colorfast, colorfastness, 6722, ISO 6722, road vehicles, voltage, cable, single core, multi-core, 43.040.10, Taber Abrasion Tester, Taber abraser, abraser, Taber, abrasion, abrasion tester, abrasion test, abrasion resistance, linear abrader.